Your I-H&S Sales team

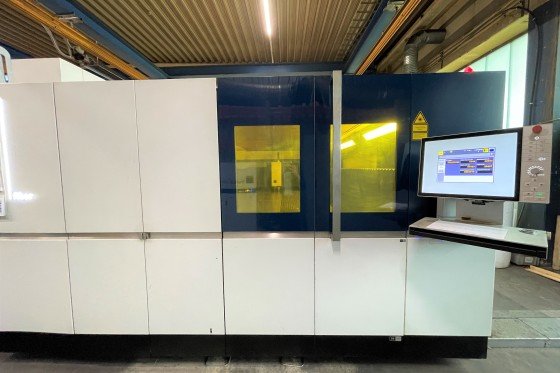

LASER CUTTING MACHINE TRUMPF TRULASER 5040 FIBER (L69), 8000 WATT, LM-1932

Standard configuration

Machine

• Closed machine frame

• Integrated cabinet

• Motion unit for high precision processing

• Torque drive in combination with direct linear drives

• Automatic pallet changer lengthwise installation

• Enclosed beam delivery via laser light cable

• Chiller for machine cooling

• Integrated electrical cabinets with inside light

• Power supply for TruDisk by the machine

• Wide longitudinal conveyor

• Ergonomic control panel with Touchscreen

• Work area lighting

• Positioning laser diode

• Spray device

• PierceLine

• FocusLine

• NitroLine

• PlasmaLine

• Automatic nozzle cleaning

Laser

• Solid state laser TruDisk 3001 with 1 fiber optic cable laser output

• Laser light cable according standard layout

• Laser chiller unit (water-air)

• Stimulation via pump diodes

• Laser power control

Cutting unit

• Universal Cutting head with complete adaptive lens system

• One cutting head strategy

• Protection glass to avoid lens contamination

• Online protection glass monitoring

• ControlLine

Control

• TruToPs Laser via network access (PC to be provided by the customer)

• Easy shop floor programming

• Fast post production

• Control Sinumerik 840D SL

• 19" Touch panel

• Technology data is integrated

• Automatic shutdown

• Programmable cutting gas pressure

• ContourLine

• Microweld

• FastLine

• AdjustLine

• FlyLine

• Integrated e-shop

Data transmission

• RJ45 network connection

• USB interface

• Wireless Operation Point

Safety

• CE label

• Light barriers

• Multi-chamber extraction system

• Compact dust extractor

• Machine enclosure with certificated window (right door)

• Electrical curl up roof

Additional equipment

• Solid-state laser TruDisk 8001 with 1 laser output (BrightLine fiber is contained in the standard scope of delivery of TruDisk 8001)

• Smart Nozzle Automation (comprises nozzle changer, nozzle inspection, Smart Skip)

• Copper cutting package

• Brass cutting package

• CoolLine

• Wide transverse conveyor with tilt container

• Door window on left side for better insight

• Integrated video camera 1 for process monitoring and single picture transmission to network

• Drop&Cut

• Right hand installation machine

• CO2 extinguishing device for compact dust extractor

• Connector, exhaust line for compact dust extractor

• MobileControl App

• MDA Interface

• Smart Beam Control (preparation focus comp)