Your I-H&S Sales team

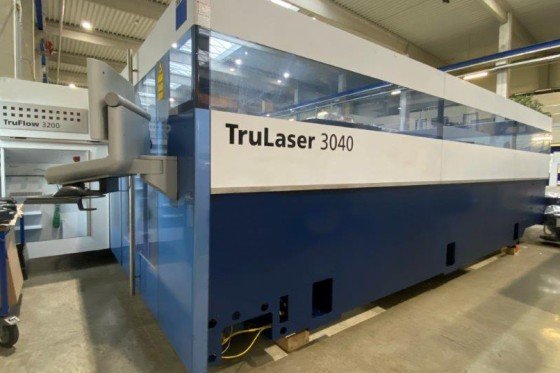

LASER CUTTING MACHINE TRUMPF TRULASER 3040 (L32), 3200 WATT, LM-1872

Standard Configuration

Machine

⦁ Closed machine frame with integrated laser unit

⦁ Motion unit for high precision processing

⦁ Torque drive in combination with direct linear drives

⦁ Enclosed beam delivery system

⦁ Chiller

⦁ Automatic pallet changer lengthwise installation

⦁ Longitudinal conveyor

⦁ 17" touch screen

⦁ Working area lighting

⦁ Positioning laser diode

⦁ Spray device

⦁ PierceLine

⦁ FocusLine

⦁ PlasmaLine

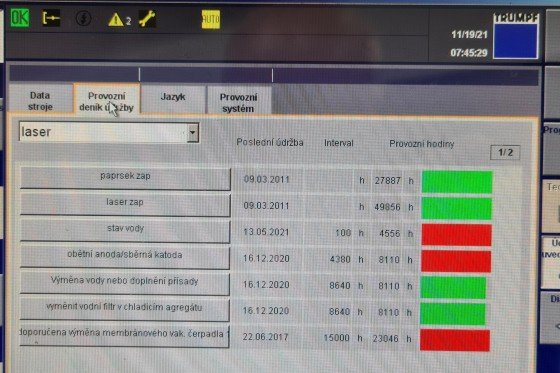

Trumpf Laser

⦁ CO2-Laser TruFlow 3200 including NitroLine, with optimized Standby Modus

⦁ beam tube purge with nitrogen

⦁ Maintenance-free radial turbine blower

⦁ Radio-frequency excitation

⦁ Laser control TASC 3

⦁ Laser power control

⦁ Logbook function Laser

⦁ Laser cutting head

⦁ One cutting head strategy

⦁ LensLine with status check

⦁ Laser cutting head with 250 mm lens

⦁ Universal quick-change device (UTI)

⦁ ControlLine: Height regulation and sheet edge detection

Control

⦁ Sinumerik 840D SL

⦁ Integrated Technology data

⦁ Automatic shutdown

⦁ Production plan

⦁ Programmable cutting gas pressure setting

⦁ ContourLine

⦁ Microweld

⦁ AdjustLine

⦁ Teleservice via internet

⦁ FastLine

⦁ FlyLine

⦁ Simple shopfloor programming

⦁ Advanced shopfloor programming

⦁ Fast post-producing

Data transfer

⦁ USB interface

⦁ RJ45 network connection

Safety

⦁ CE marking

⦁ Light barriers

⦁ Laser monitoring system

⦁ Multi-chamber extraction system and compact dust extractor

⦁ Machine enclosure consisting of Macrolon panels